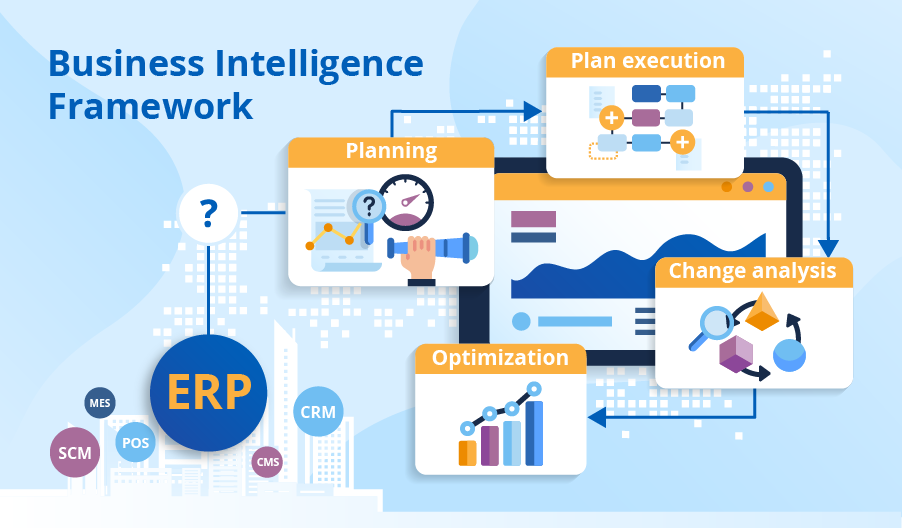

Based on our 17 years of experience in BI implementation, we developed a BI framework that allows utilizing data for more structured fact-based decisions. The framework embraces four main components: planning, plan execution, change analysis and optimization. Let’s look at each component separately and check whether the data in a company’s enterprise resource planning (ERP) system is enough to get valuable insights and which other data sources to turn to if ERP data is insufficient or missing.

Planning

The planning component embraces trend analysis, forecasting, and performance analysis.

Trend analysis

Examining only ERP data to identify trends can result in misleading insights. For instance, a manufacturer sees no growth in shipments to a particular region and concludes that the situation remains stable. In reality, the demand for the manufacturer’s products in this region is increasing. The ERP system doesn’t reflect this trend as it’s unaware of unmet demand: the enterprise is working at its full capacity and successfully selling everything it produces. However, if the manufacturer turned to their CRM data, they would find there the increased number of lost opportunities with ‘No product available’ clarification.

Forecasting

We don’t think that an ERP system is enough for forecasting. Say, to predict customer demand, data from internal and external sources is required, such as detailed sales history (ERP and POS systems), a customer’s location and type (CRM), weather conditions or social media trends (external sources).

Performance analysis

Internal benchmarking also requires not only ERP data. For example, to identify their top-selling stores, a retailer should analyze sales values taken from a POS system, as well as consider the sales floor area and the number of available checkouts, which can be stored in their ERP.

Plan execution

ERP data may be enough to analyze the performance against the plan and spot deviations. However, to run root cause analysis, a company often needs to go beyond ERP data. Say, if a manufacturer has failed to achieve their production plans, they may find the reason in the disrupted deliveries of raw materials by some of their Tier 1 suppliers. To get to these details, a manufacturer has to turn to SCM (supply chain management) data.

Change analysis

ERP can be one of the data sources for change analysis. It’s fine to conduct ROI analysis, as finances and assets are tracked in an ERP system. On the other hand, ERP data won’t help in analyzing the effect of redesigning a company’s online store, while the data (i.e., product lists, pictures, descriptions and visitors’ search and purchase histories) from a content management system and an e-commerce solution will be required for this purpose.

Optimization

We don’t recommend companies to rely solely on ERP data if they challenge themselves with business process optimization. Take asset management as an example: ERP is likely to contain just machinery name, purchasing date, and price. If a company strives to use their machinery efficiently and reduce overall costs through preventive and even predictive maintenance, they need to know equipment utilization and maintenance schedules. And this info is usually stored in an MES (manufacturing execution system) or dedicated equipment utilization software.

To sum it up

Though ERP is a vital source of data for BI, we don’t recommend embedding business intelligence into ERP. BI can only bring value when it’s on top of all the company’s applications, such as ERP, CRM, SCM, CMS, MES, and POS, and when it uses external data sources.