Opening and Urgent Issues

Have you noticed that total production capacity is not keeping up with demand (just a 0.4% growth rate year-on-year in Q3 2023 while demand rises; Source: UNIDO)? With uncertainties in Cost Control, Cost Improvement, Supply Chain, and Technological Advances (expensive/uncertain/slow implementation), the “customer is king” era is on the decline. Gone are the days when everything that was produced and sold was sufficiently profitable. It’s now crucial to meet the needs of all key stakeholders by achieving target profitability, beyond just satisfying customers.

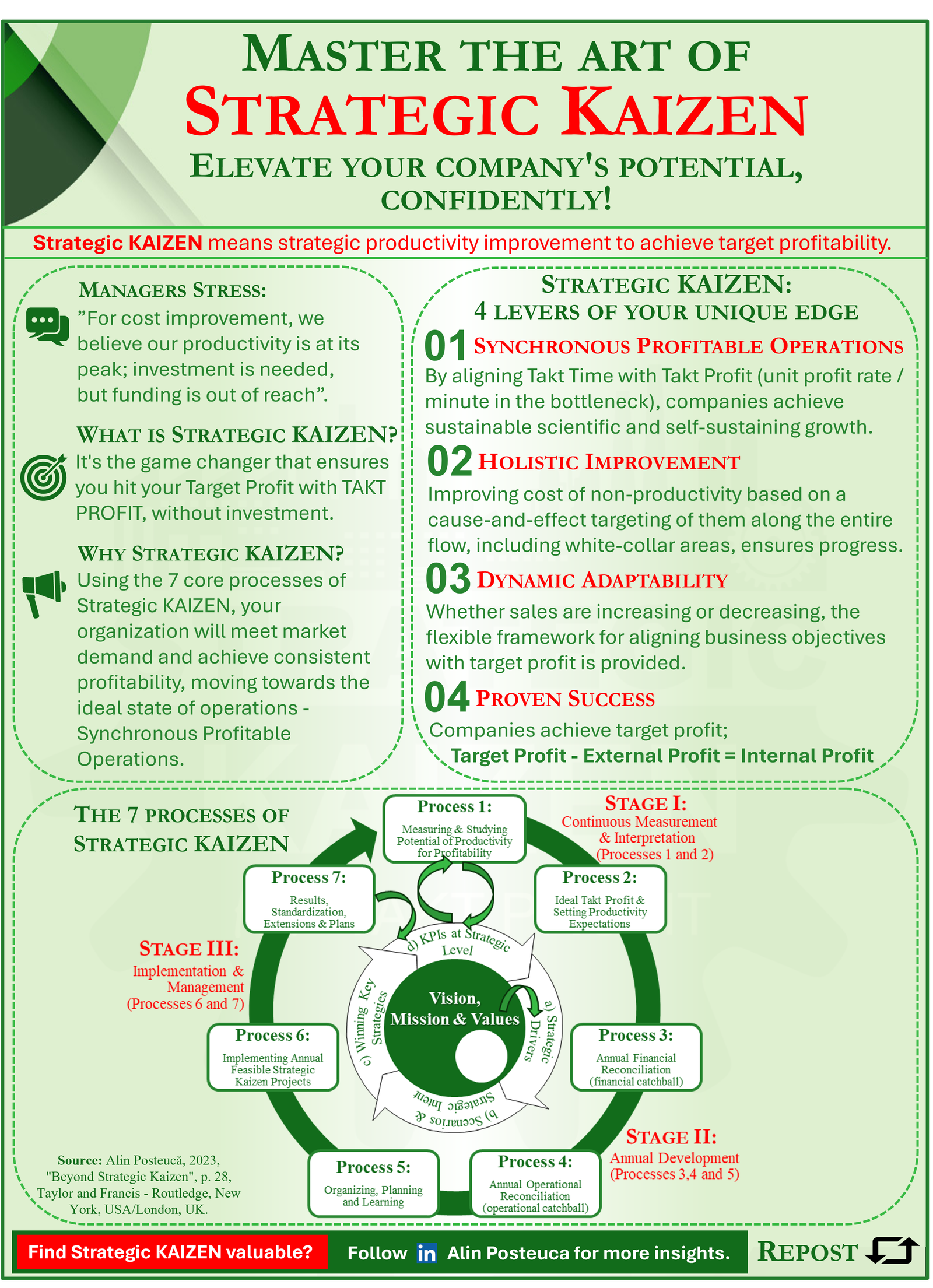

Moving on, UNIDO’s alarming statistics resonate with the pressing challenges faced by manufacturing managers. They often highlight the gap between expected and actual costs, the disparity in cost structures compared to competitors, and the difficulty in further reducing costs, particularly indirect ones, like this:

(a) “The gap between our target cost and actual achievement is vast, especially with rising raw material and utility costs.” — Plant Manager, automotive industry.

(b) “We know our overhead costs are high compared to other companies, but we lack a clear improvement strategy.” — Managerial Accounting Manager, food industry.

(c) “We believe our productivity has peaked, but we need investment to cut costs further, which is out of reach.” — Production Manager, food industry.

(d) “It’s tough to remain cost-competitive by only cutting direct costs; we need a holistic approach.” — Sales Manager, chemical industry.

There’s an urgent need to enhance all productivity factors. That’s precisely where Strategic KAIZEN comes in.

Master the Art of Strategic KAIZEN

Strategic KAIZEN aims to achieve synchronous profitable operations by aligning Takt Time with TAKT PROFIT, thus achieving Target Profit through continuous productivity improvement. This approach ensures companies not only meet market demand effectively but also maximize profitability without additional investment, in this way ensuring the added value necessary for the Company and Customers.

For top managers, Strategic KAIZEN is the pathway to operational excellence and financial success. Strategic KAIZEN thrives on teamwork, where the ongoing, visible involvement of top managers is crucial to achieving the desired results at both the KAIZENshiro Budget and operational levels. Sharing managerial experiences and the Strategic KAIZEN approach across departments streamlines the entire process. Please see the figure below:

The Strategic KAIZEN Journey

The journey of creating, developing, applying, and publishing Strategic KAIZEN by Dr. Alin Posteucă commenced in mid-October 1995 during a Computer Aided Design of Business Systems course at the University of Iasi, aimed at incorporating JIT thinking.

Over the years, Strategic KAIZEN has evolved into a framework that seamlessly aligns operational processes with financial objectives, ensuring every strategic productivity improvement effort directly contributes to achieving strategic goals and target profitability.

By systematically eliminating all operational barriers to target profit without requiring additional investment, the approach has guided organisations through economic uncertainties, enhancing cost competitiveness and securing long-term success.

Please see the figure below.

The KAIZENshiro culture, focusing on the strategic improvement of cost of non-productivity, embodies a collective mission. This culture fosters collaboration, innovation, and a relentless pursuit of excellence, making your organisation resilient and future-focused.

Key Benefits of Strategic KAIZEN

By embedding Strategic KAIZEN within your company, you unlock several core advantages that drive both immediate and long-term success. Let’s delve into the key benefits that make Strategic KAIZEN an indispensable strategy for top-tier managers:

- Increased Profitability: Integrating financial objectives into operational strategies ensures every strategic productivity improvement effort contributes directly to both the financial and operational bottom lines;

- Sustainable Growth: Embedding systematic strategic improvement within organisational culture fosters long-term success and adaptability;

- Operational Excellence: Optimised processes reduce waste and losses, leading to higher productivity (cost improvement) and quality,

- Implementation: The Strategic KAIZEN methodology guides organisations through continuous measurement, interpretation, and systematic improvement. It is designed to be adaptable to various market conditions, ensuring that your organisation remains competitive and profitable, continuously operating and growing.

Now is the time for top managers to act decisively. Time seems to have run out of patience with many organizations. Implement Strategic KAIZEN and unlock the potential for unparalleled growth and profitability. Let’s make it happen.

Thank you for dedicating your valuable time to read this article. I genuinely hope it serves as a source of inspiration for your endeavours.

Dr. Alin Posteucă