Opening and Urgent Issues

Are you ready to transform your organization’s productivity and cost competitiveness in 2025 and beyond?

As we look ahead, the top priority for production reform is clear: improving cost competitiveness (86% of organizations urgently need this). Yet, a significant challenge looms – 73% of organizations report that productivity improvements are neither sufficient nor strategic. This dissatisfaction highlights a critical gap in how organizations are managing their productivity initiatives.

According to Harvard Business Review (2024), while 89% of large companies globally are pursuing digital and AI transformations, they have only realized 31% of the anticipated revenue growth and 25% of expected cost savings from these efforts. This underperformance raises an urgent question: Are we truly leveraging our resources effectively?

Many organizations struggle with productivity initiatives, often resorting to ad hoc measures like waste elimination or mimicking successful case studies. However, these approaches frequently fail to deliver sustainable results. Until business leaders align on a clear strategic direction for productivity growth, revitalization efforts will remain sluggish.

The root of the issue lies in a lack of clarity regarding where cost of non-productivity occur, how to quantify them, and the specific actions needed for improvement. Establishing a comprehensive plan that outlines who will implement changes, what those changes will be, and how they will be executed is essential. By focusing on these elements, organizations can drive visible, strategic productivity growth that supports ongoing cost improvements and enhances competitive advantage. This is exactly what the Strategic KAIZEN methodology does.

Are you prepared to take decisive action and redefine your productivity strategy today? Leverage KAIZENshiro Costing to drive continuous improvement in your Strategic KAIZEN projects.

While we recognize the necessity for price adjustments, it’s crucial to maintain our commitment to quality without compromise. Currently, we are facing stagnant sales growth (or even steep sales declines), and our efforts in cost reduction are not advancing as needed. Implementing Strategic KAIZEN can drive comprehensive productivity enhancements tailored to your company’s unique needs, ensuring significant financial and operational gains. This approach not only enhances productivity to achieve cost reduction and profitability targets, but also aligns your team with long-term goals.

Understanding KAIZENshiro Costing: A Dual Concept for Continuous Improvement

Are your non-productivity costs undermining your competitive edge? As the manufacturing landscape becomes increasingly challenging due to rising material and transformation costs, addressing KAIZENshiro Costs -total non-productivity costs – has never been more critical.

To enhance cost competitiveness, companies must focus on two key strategies: reducing unit prices and minimizing usage times and quantities. While productivity improvements in production have traditionally been prioritized, many organizations find their efforts yielding minimal results.

The term KAIZENshiro merges two powerful concepts: “KAIZEN” and “shiro.” While the concept of KAIZEN—rooted in Japanese philosophy—focuses on continuous improvement to enhance value, the term “shiro” warrants further exploration.

“Shiro,” also of Japanese origin, translates to “white,” symbolizing purity and innocence. However, it encompasses more than just a color; it signifies the margins and spaces necessary for growth and innovation. In a business context, “shiro” represents the essential areas where potential can flourish, allowing organizations to create room for new ideas and improvements.

By integrating KAIZEN with shiro, we embrace a holistic approach to continuous strategic improvement, fostering an environment where innovation can thrive within defined boundaries. This synergy not only drives efficiency but also cultivates a culture of excellence.

In the Strategic Kaizen methodology, the concept of “shiro” – which translates to margin, necessary area, or purity—represents the theoretical target for minimizing the costs associated with non-productivity. This approach aims to enhance both the current manufacturing cost levels and future cost targets by eliminating the costs of non-productivity. The goal is to achieve a manufacturing cost structure that is as “white” as possible, maximizing value for all key stakeholders – beyond just customers.

Optimizing Non-Productivity Costs for Strategic Improvement and Takt Profit Achievement

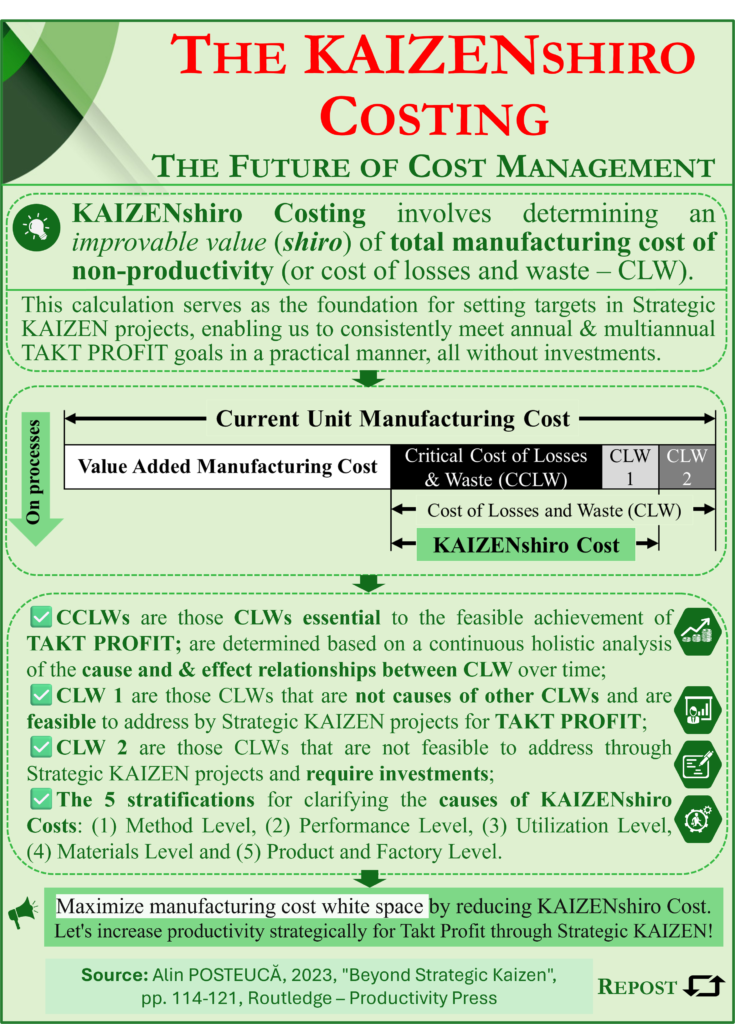

To drive effective and efficient strategic improvements, Strategic KAIZEN projects, it is essential to structure and quantify total non-productivity costs continuously. This process spans from the procurement of raw materials to the delivery of finished products to customers. See the figure below.

By identifying and allocating cost of losses and waste at each stage of the process, we can enhance our overall productivity and achieve TAKT PROFIT targets through Strategic KAIZEN projects.

The concept of the year of improvement scenario to simultaneously overcome capacity and profitability constraints – regardless of the sales trend.

To all managers:

As we pursue our annual Takt Profit targets through Strategic KAIZEN projects,it is crucial to assess the feasibility of improving each type of CCLW and CLW. We must also address and overcome traditional constraints to achieve impactful results that are clearly reflected in the KAIZENshiro Budget.

Identifying and clarifying these constraints in our Strategic KAIZEN policy proposals is vital for driving meaningful outcomes and progressing toward our goal of synchronized profitable operations (SPO).

Assess your current processes, challenge the status quo, and embark on the journey to operational excellence with Strategic KAIZEN.

Thank you for dedicating your valuable time to read this article. I genuinely hope it serves as a source of inspiration for your endeavours.

Dr. Alin Posteucă