Have you ever used a product and felt that it was pleasing to use and exuded high quality, but you couldn’t quite figure out why? Often subtle features in a product’s design will set them a cut above the rest. Sometimes it doesn’t take much: a subtle curve here and there, a textured finish, or simply weight in the right place. Another subtle injection moulding feature where industrial designers can make a massive difference is in overmoulding.

Keep reading to find out how you can use overmoulding in your product design to sit a notch above the rest so that your product is the first that customers reach for. For a more technical and in-depth overmoulding article, see “What is Overmoulding? An Overview and Guide” or read this article on injection moulding first if you are new to injection moulding.

Power Drills are perhaps the most common application of overmoulding. Hilti are exemplars in high quality injection moulding and overmoulding – check out that texturing on the grip on the Sf 4h-22 Cordless Hammer Drill Driver!

What Is Overmoulding? A Brief Overview

Overmoulding — also known as overmolding or co-molding — is a plastic injection moulding technique that allows different plastic materials to be applied to the product in the same injection moulding process, without the need for assembly. The second material can either partially or fully encapsulate the primary material (also called the substrate).

It is used in a wide variety of industries and applications and is commonly visited in product development. The reasons for using overmoulding vary greatly and its applications are endless, including increasing grip, sealing products, shock protection, and improving a product’s look and feel. These applications are endless, provide extra value to your product, and can reduce assembly costs if the injection moulding company is fitted with robots to place the substrate into the injection moulding machine automatically.

While many materials can be used for plastic overmolding, the main combinations are:

- A soft plastic over a hard plastic – Often for grip, aesthetics, and waterproofing

- A hard plastic over a hard plastic – Often for increased protection, strength, and durability, or concealing and waterproofing electronics

- A hard plastic over a soft plastic/foam – For higher strength-to-weight qualities

- A soft/hard plastic over metal – Often to incorporate fixings, metal threads, or sensors.

Using Over-Moulding To Improve How Your Product Works

The possible applications for over-moulding are vast and always increasing — it simply depends on the industrial designer’s creativity, and the injection moulder’s ability.

Improving Grip – Perhaps the most used application of overmoulding, a soft rubberised plastic such as a TPE or TPU is over-moulded over various hard plastics like ABS in order to increase grip. Think of toothbrushes, power drills, steering wheels, or grips on computer mouses. The Hilti Drill shown at the start of the article is a perfect example of overmoulding for grip – zoom in and check out the diamond-hatch texturing on the grip. A work of art!

Incorporating Flexible Areas – Sometimes soft plastics are moulded over rigid components, to offer flexible sections for various applications. Examples include soft-headed kitchen utensils and shower suction cups.

The Dreamfarm Set of Essentials —designed here in Brisbane by their fantastic team of in-house industrial designers —is a great example of overmoulding to create a flexible surface. They’ve even taken the opportunity to use the soft coloured plastic into the eye loop for visual appeal.

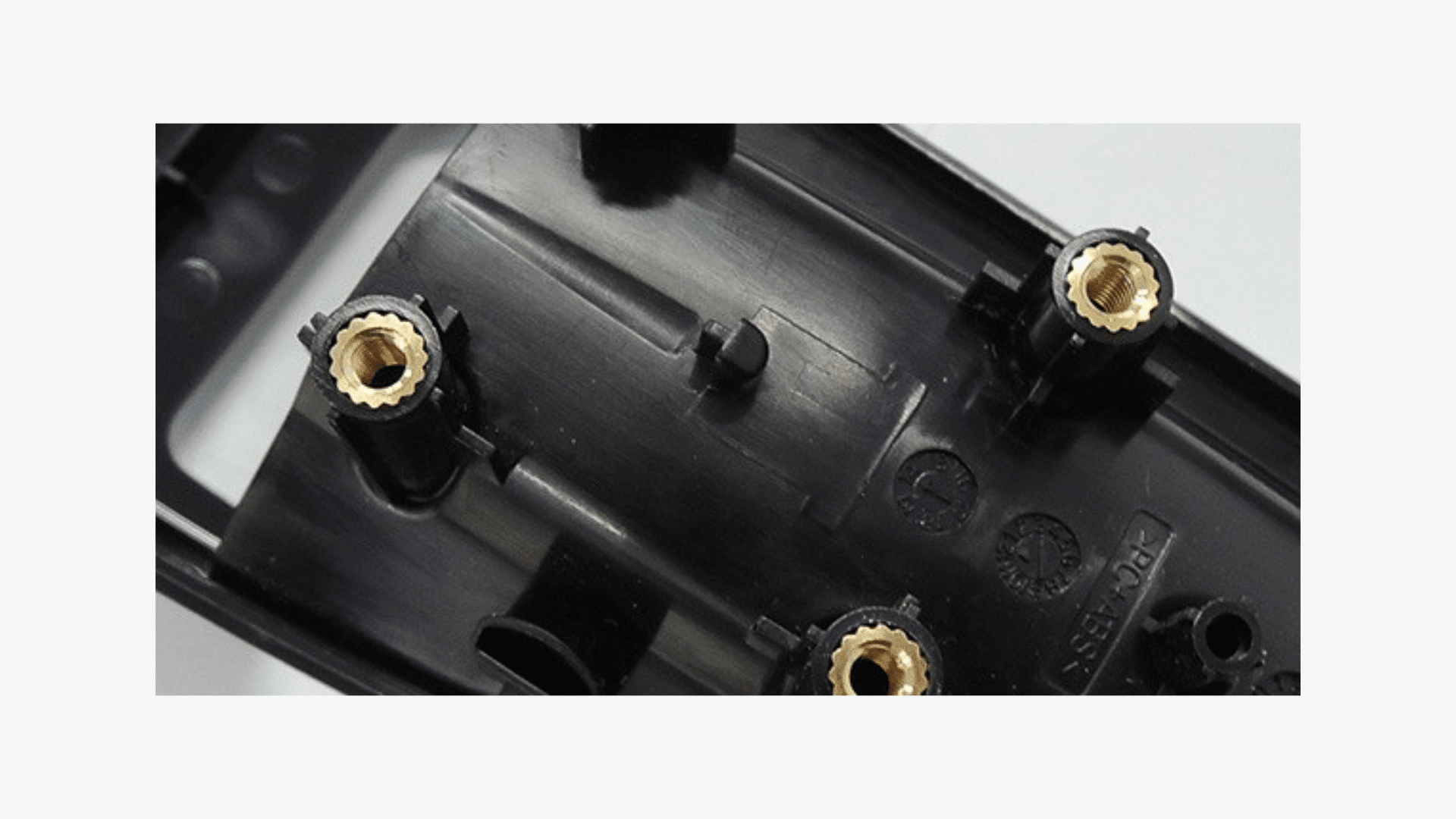

Inserted Fixings and 3D-Printed Parts – Fixings can be overmoulded securely in place in a product, allowing for strong fixings which are commonly metal threads inserts, magnets, threaded rods, or other metal fixings. Less commonly, custom 3D-printed parts can be overmoulded, which offers the ability for 3D printed parts to be changed over time as needed, with the rest of the mould remaining the same.

Here, threaded inserts are overmoulded in place when injection moulding, to create strong fixing points for installation/assembly applications.

Inserted Circuitry – Sensors, circuit-boards, and cables can be overmoulded to be embedded in products to have sensors in places where would otherwise be impossible. More on this in our next article on overmoulding in plastic injection moulding.

Most PVC electrical cables are overmoulded, placed by hand into a vertical injection moulding unit. This is a very secure and water-resistant method to attach cable ends to the rest of the cable.

Hygienic Sealed Products – Medical products and electrical medical implants can be completely overmoulded to seal off internal circuitry.

Elevating Your Product Design’s Look & Feel

Overmoulding isn’t just useful for how your product is used, but also in how it looks and feels. It is a strong opportunity for compelling product design.

Soft Texture to Touch – An otherwise simple product’s appeal can be elevated by simply using a soft plastic overlay to provide a different look and feel. The overmould can be applied in varying textures and shapes by the product designer to reflect the brand and desired aesthetic. Silicone rubber is renowned for being pleasing to touch, though modern TPEs and TPUs can perform just as well in most cases and are much easier to injection mould.

The Laserforce Gen8 Phaser & Chestpack both use overmoulded TPE – whilst on the Phaser it is primarily used for improving grip, the look is continued throughout the parts to provide a compelling aesthetic by its contrast with the diffused lighting.

Adding Graphics To Make Branding Pop – Different graphics and patterns can be displayed using overmoulded plastics, or to accentuate a brand’s logo placement. Normally, this is only done when the overmoulding process is already being used for another purpose in the product’s design, as employing overmoulding can be expensive due to the need in most cases of a second injection moulding tool.

Many water bottles – including this Nike bottle above – use overmoulding for their grips, but their industrial designers also take the opportunity to shape these for aesthetic appeal. Note that the Nike tick here is made via a window in the overmoulding, which is a very durable way of ensuring your branding is never rubbed off – which can happen when pad-printing.

Conclusion

Tune in next time to “Why the Best Product Designs Use Overmoulding, and Why Yours Should Too – Part 2”, to learn about how overmoulding creates more robust electronic devices, which industries most suit over-moulding, and financial and environmental costs of overmoulding.

If you’re interested in other ways to incorporate branding into your product rather than overmoulding, see our blog on branding methods here.

At Dienamics, we offer a range of comprehensive services in every step of the product manufacturing process. These include:

Contact us today if you have a product you’re looking to get designed & manufactured!